Steyr, Austria, March 2023. At this year’s Hannover Messe, NKE Austria GmbH will present bearings for wind turbine gearboxes and generators. The Austrian bearing manufacturer has more than 20 years of experience in the wind energy sector. NKE bearings have been installed in more than 4,000 wind turbines across Europe, the USA and China, equivalent to more than 10,000 MW of installed power.

“NKE bearings are used in the most important wind turbine components, that is gearboxes and generators, or as main bearings. We have final product approvals with major wind turbine manufacturers and are in the final stages of the approval process with others,” says Matthias Ortner, Managing Director of NKE in Steyr. “The strategic focus on sustainable technologies such as wind power and rail vehicles that was introduced three years ago is now bearing fruit. NKE is gaining a reputation as an innovative supplier of bearings for wind power.”

For example, NKE bearings are present in all bearing applications of the Envision gearbox: from the carrier (rotor side, generator side) to the high-speed shaft, including the intermediate shaft and planetary gearbox shafts. “For high-speed shafts, NKE cooperates with the customer’s engineering team to design bearings with enhanced profile and contact pressure,” says Michael Rössl of NKE’s Application Engineering department. “Another example are our new bearings with Power-Density technology: they are only 20 percent larger than conventional bearings, but they generate twice as much energy to optimize the output of the wind turbines and extract as much energy as possible from the air stream.”

At the company headquarters in Steyr, Austria, NKE has established a competence centre for large bearings, including the most advanced production facilities and a logistics centre. All NKE bearings undergo strict, documented quality control procedures. Besides comprehensive technical consulting services, NKE’s Application Engineering department offers support for obtaining certification to wind standards such as GL2010, IEC61400 or individual customer specifications.

Besides bearings for wind power, NKE produces standard and special bearings for all industrial applications. Engineering, product development, production and final processing of components, assembly, quality assurance, logistics, and sales and marketing are centralized at its Steyr headquarters. In addition to product development and application engineering, NKE provides a full range of technical services, consulting, documentation and training.

NKE at Hannover Messe 2023:

17 to 21 April 2023, Hannover, Germany, Hall 5 Booth B05

Picture:

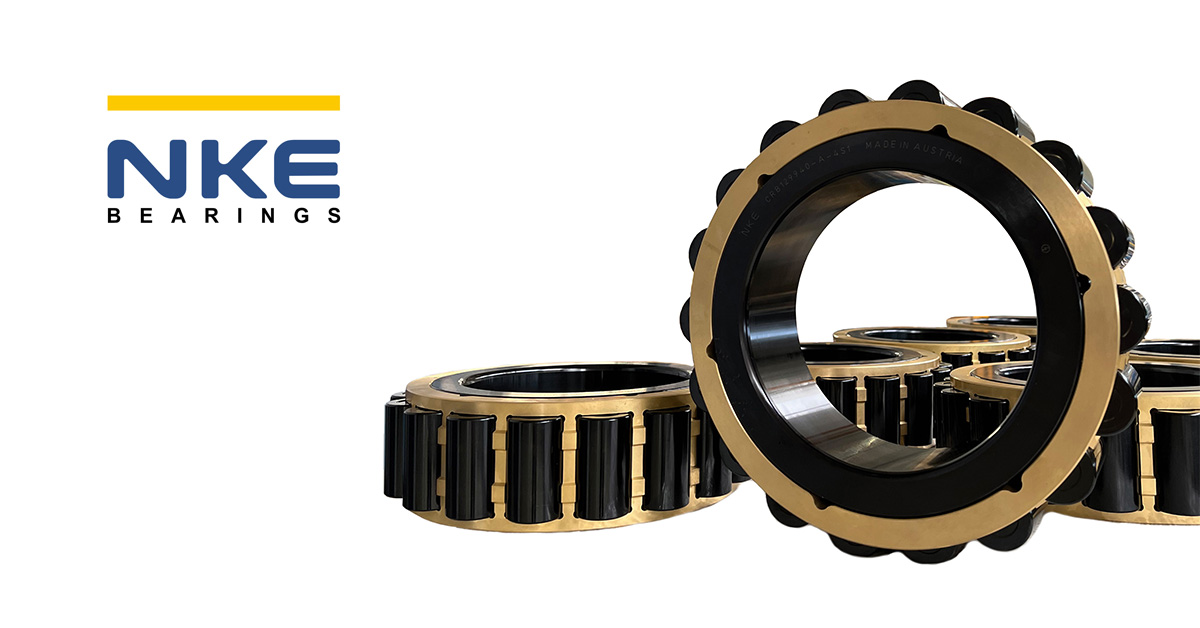

Cylindrical roller bearings with black oxide finish from NKE. Bearings used in wind turbine gearboxes are commonly coated with black oxide. This special treatment forms a protective layer on the functional surfaces of a bearing. Among other advantages, black oxide finished bearings offer improved run-in and wear and enhanced adhesive wear characteristics.